In recent years, the global push to reduce plastic waste has gained significant momentum. Plastic pollution is a severe environmental issue, with plastic waste affecting oceans, wildlife, and ecosystems. As consumers and businesses alike seek sustainable alternatives, molded pulp products have emerged as an innovative solution in the fight against plastic waste. These products, made from recycled paper pulp, offer a biodegradable and environmentally friendly alternative to traditional plastic packaging and products. This article will explore how molded pulp products are helping reduce plastic waste, their applications, benefits, and the challenges they face.

The Growing Environmental Crisis of Plastic Waste

Plastic waste has become one of the most significant environmental challenges of the 21st century. With millions of tons of plastic waste entering the environment every year, the consequences are dire. Much of this plastic ends up in landfills, oceans, and other ecosystems, where it can take hundreds of years to break down. This has led to the accumulation of microplastics in the environment, harming marine life and even entering the food chain. Plastic pollution has been identified as a key factor in the loss of biodiversity, as animals often mistake plastic for food or become entangled in it.

In response to this crisis, the world is looking for viable solutions to reduce the production and use of plastic. Governments, corporations, and individuals are exploring eco-friendly alternatives that can replace single-use plastic items. Molded pulp products have gained significant attention due to their potential to replace plastics in a wide range of applications. Made from renewable resources such as recycled paper, molded pulp products are biodegradable, recyclable, and offer a sustainable alternative to plastic.

What Are Molded Pulp Products?

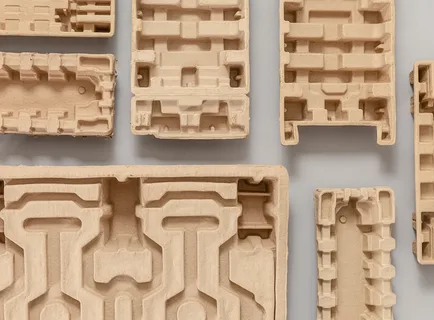

Molded pulp products are created through a process that involves shaping recycled paper pulp into various forms. The process typically involves mixing recycled paper with water to create a pulp, which is then molded into specific shapes using a mold. The pulp is dried and hardened, resulting in durable, lightweight products. This process allows for the creation of a variety of items, including packaging, trays, containers, and even single-use items such as cups or plates. Because molded pulp products are made from recycled paper, they are not only biodegradable but also help reduce the amount of paper waste that ends up in landfills.

One of the main advantages of molded pulp products is their versatility. They can be molded into different shapes and sizes, making them suitable for various applications, from food packaging to electronics protection. Additionally, molded pulp is compostable, which means that it will naturally break down into non-toxic components over time, making it a far more eco-friendly option than plastic. This makes it an ideal material for use in packaging, where waste reduction and sustainability are becoming top priorities for consumers and businesses alike.

The Environmental Benefits of Molded Pulp Products

Molded pulp products offer several environmental benefits that make them an attractive alternative to plastic. First and foremost, they are biodegradable, meaning that they break down naturally in the environment without causing long-term pollution. Unlike plastic, which can take centuries to decompose, molded pulp products decompose quickly, leaving no harmful residues behind. This is especially important in the context of packaging, as single-use plastic items often end up in landfills or oceans, where they persist for hundreds of years.

In addition to being biodegradable, molded pulp products are made from recycled materials, primarily paper. By repurposing paper waste, they help reduce the demand for new raw materials, such as trees. This contributes to deforestation prevention and reduces the overall environmental impact of manufacturing. Furthermore, because molded pulp products are recyclable, they can be reused in the production of new products, contributing to a circular economy. As such, molded pulp products help conserve natural resources, reduce waste, and minimize environmental damage associated with plastic production and disposal.

Applications of Molded Pulp Products in Various Industries

Molded pulp products have a wide range of applications across various industries, making them a highly adaptable alternative to plastic. In the packaging sector, molded pulp is commonly used for protecting fragile items such as electronics, glass, and ceramics. It provides a secure and protective cushion for products during shipping and handling, ensuring that they arrive undamaged. Molded pulp packaging is an effective substitute for plastic clamshells, foam peanuts, and bubble wrap, all of which are typically difficult to recycle and contribute significantly to plastic waste.

In the food and beverage industry, molded pulp products are increasingly being used for single-use items such as plates, bowls, and trays. Unlike plastic alternatives, these products are compostable and biodegradable, making them ideal for takeout and foodservice operations that prioritize sustainability. Additionally, molded pulp products are used for egg cartons, which have been a staple in food packaging for many years due to their ability to protect eggs during transit. As consumer demand for eco-friendly products grows, many companies are switching from plastic packaging to molded pulp alternatives to reduce their environmental footprint.

Challenges and Future of Molded Pulp Products

While molded pulp products offer numerous environmental advantages, they are not without their challenges. One of the primary concerns is their production cost, which can be higher than that of plastic. The molding process requires specialized equipment and raw materials, and while recycled paper is used, the cost of sourcing, processing, and manufacturing molded pulp can be prohibitive for some companies. Additionally, while molded pulp is biodegradable, it can still have a significant environmental footprint if not properly managed. Recycling systems for molded pulp products are not yet as widespread as plastic recycling systems, which can limit their effectiveness in some regions.

The future of molded pulp products, however, looks promising. With increasing demand for sustainable packaging and a growing awareness of the environmental impact of plastic, molded pulp products are expected to become more prevalent. Research and development in this field are likely to lead to more cost-effective production methods, making molded pulp a more accessible option for businesses of all sizes. As the world continues to focus on reducing plastic waste and transitioning to more sustainable materials, molded pulp products have the potential to play a significant role in the fight against plastic pollution.

Conclusion

Molded pulp products represent a promising and sustainable solution in the battle against plastic waste. Made from recycled paper pulp, these products are biodegradable, recyclable, and compostable, offering a significant reduction in plastic usage across various industries. From packaging to foodservice, molded pulp products are replacing traditional plastic items with eco-friendly alternatives. While challenges remain, such as production costs and recycling infrastructure, the future of molded pulp products looks bright as businesses and consumers increasingly prioritize sustainability. As technology advances and the demand for environmentally friendly products grows, molded pulp has the potential to help reduce plastic waste and contribute to a more sustainable future for the planet.