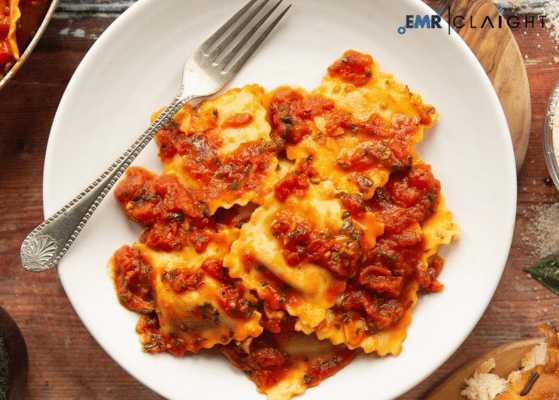

Pre-made ravioli has become a staple in the convenience food market, appealing to consumers who seek high-quality, ready-to-cook meal options. Known for its versatility, ravioli is a filled pasta that can be customised with various fillings such as cheese, meat, or vegetables. Establishing a pre-made ravioli manufacturing plant involves thoughtful planning, adherence to food safety standards, and leveraging automation to meet the growing demand for this delicious and convenient product. With the increasing popularity of pasta-based dishes worldwide, investing in a ravioli manufacturing facility offers a lucrative business opportunity.

Understanding Pre-Made Ravioli and Its Market

Pre-made ravioli is a type of stuffed pasta that is pre-packaged for retail or food service distribution. This product is valued for its convenience, as it can be quickly cooked and served, making it a favourite among busy households and restaurant chefs. The market for pre-made ravioli is expanding globally, driven by factors such as changing consumer lifestyles, growing preference for Italian cuisine, and demand for premium convenience foods.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/pre-made-ravioli-manufacturing-plant-project-report/requestsample

Key Applications of Pre-Made Ravioli:

- Retail Market

Pre-made ravioli is widely sold in supermarkets and grocery stores as a ready-to-cook meal option, catering to families and individuals. - Food Service Industry

Restaurants and catering businesses use pre-made ravioli to streamline operations, reduce preparation time, and maintain consistency in quality. - Frozen Food Market

Pre-made ravioli is a significant product in the frozen food segment, offering extended shelf life and easy storage. - Specialty Food Stores

Artisanal and gourmet versions of ravioli, featuring unique fillings or organic ingredients, are popular in specialty food markets.

Steps to Establish a Pre-Made Ravioli Manufacturing Plant

1. Market Research and Feasibility Analysis

Conduct comprehensive market research to understand consumer preferences, demand trends, and competitor offerings. Analyse target demographics and potential markets, including domestic and international opportunities. A feasibility study will help evaluate technical, financial, and operational aspects of the project.

2. Location Selection and Facility Design

Choose a location that offers access to raw materials, skilled labour, and transportation networks. The facility should comply with Good Manufacturing Practices (GMP) and include dedicated zones for raw material storage, dough preparation, filling production, pasta shaping, packaging, and storage.

3. Raw Material Procurement

Secure a reliable supply of high-quality raw materials, including flour, eggs, fillings (cheese, meat, vegetables), and packaging materials. Establish partnerships with trusted suppliers and ensure ingredients meet food safety and quality standards.

4. Production Machinery and Technology

Invest in advanced machinery to streamline the manufacturing process. Essential equipment includes dough mixers, pasta sheeters, filling injectors, ravioli cutters, and packaging machines. Automation in production improves efficiency, reduces waste, and ensures consistent product quality.

5. Recipe and Product Development

Develop a variety of recipes to cater to diverse consumer preferences. Offer classic options such as cheese and spinach or create unique fillings like butternut squash or seafood. Collaborate with culinary experts to refine taste and texture.

6. Packaging Innovation

Choose packaging solutions that preserve freshness and enhance product appeal. Options include vacuum-sealed bags, recyclable containers, or frozen packaging. Highlight key attributes such as “homemade taste,” “organic ingredients,” or “quick cooking” to attract consumers.

7. Quality Assurance and Food Safety

Implement robust quality control measures at every stage of production. Adhere to food safety standards such as Hazard Analysis and Critical Control Points (HACCP) to ensure product safety and compliance with regulatory requirements.

8. Regulatory Compliance

Comply with local and international food safety regulations to ensure smooth operations and market access. Obtain necessary certifications such as ISO 22000 or FDA approvals (for US markets) to build consumer trust.

9. Workforce Training

Train employees in food safety protocols, equipment handling, and quality assurance procedures. A skilled workforce ensures efficient operations and high-quality production.

10. Sustainability Practices

Incorporate sustainable practices in manufacturing, such as using eco-friendly packaging, minimising food waste, and sourcing ingredients responsibly. These efforts appeal to environmentally conscious consumers and reduce environmental impact.

Benefits of Pre-Made Ravioli

Pre-made ravioli offers numerous benefits, making it a popular choice among consumers and food service providers:

- Convenience

Ready-to-cook ravioli saves time and effort, making it an ideal choice for busy lifestyles. - Versatility

Ravioli can be paired with various sauces and sides, allowing consumers to create diverse meals. - Consistent Quality

Manufacturing processes ensure uniform size, shape, and filling distribution, offering consistent taste and texture. - Extended Shelf Life

Vacuum-sealed or frozen ravioli retains its freshness and quality over time. - Appealing to All Ages

From children to adults, ravioli’s taste and simplicity make it a favourite across age groups.

Challenges in Pre-Made Ravioli Manufacturing

Raw Material Sourcing

Ensuring a consistent supply of high-quality ingredients can be challenging, particularly for specialty or seasonal fillings.

Food Safety Standards

Meeting stringent food safety regulations requires regular monitoring, thorough documentation, and adherence to established protocols.

Market Competition

The pasta market is competitive, with numerous brands offering similar products. Differentiating your ravioli through quality, innovation, or branding is essential.

Technological Investment

Modern machinery and automation systems require significant upfront investment and skilled operators.

Opportunities in the Pre-Made Ravioli Market

Growing Demand for Convenience Foods

The rising preference for quick and easy meal solutions presents a significant market opportunity for pre-made ravioli.

Expansion in Emerging Markets

Developing economies with growing middle-class populations and increased disposable incomes offer untapped potential for premium pasta products.

Health and Wellness Trends

Offering health-focused ravioli options, such as gluten-free or organic varieties, caters to health-conscious consumers.

Innovation in Flavours and Fillings

Developing unique and exotic ravioli fillings can attract adventurous eaters and expand your market share.

Marketing and Distribution Strategies

- Retail Partnerships

Collaborate with supermarkets, grocery stores, and specialty food outlets to distribute your products widely. - Digital Marketing

Leverage social media, e-commerce platforms, and food blogs to promote your brand and highlight the benefits of pre-made ravioli. - Sustainability Messaging

Emphasise eco-friendly practices and responsibly sourced ingredients to appeal to environmentally conscious consumers. - Participation in Food Shows

Showcase your ravioli at food expos and trade shows to connect with potential buyers and industry stakeholders. - Direct-to-Consumer Sales

Offer online sales and doorstep delivery options to reach tech-savvy customers seeking convenience.